All IP Office control units and external expansion modules can be rack mounted into standard 19" rack systems. Each unit requires a 2U slot space within the rack. Rack mounting requires a kit for each control unit and external expansion module.

Where systems are being rack mounted, the effect of conditions within the rack cabinet must be considered. For example, the rack temperature may be above the room temperature and airflow within the rack is restricted. The environmental requirements for the individual IP Office units are still applicable inside the rack cabinet.

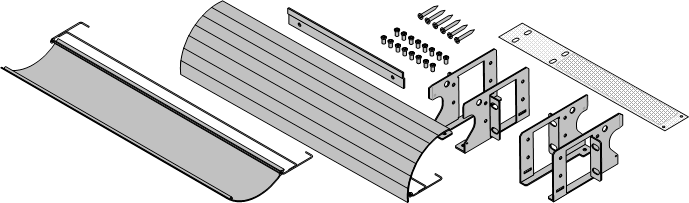

•IPO IP500 WALL MNTG KIT V3 (SAP Code 700503160)

This kit can be used for wall and rack mounting of IP500 V2 control units and IP500 external expansion modules. The kit incorporates cable routing at the front and rear of the unit. For wall mounted control units, it allows orientation of the control unit base card slots to the left or to the right.

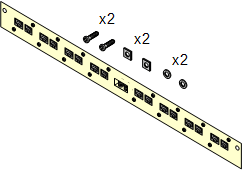

•IPO IP500 RACK MNTG KIT (SAP Code 700429202)

This kit contains all the components required for the rack mounting of a single IP500 V2 control unit or IP500 external expansion module. This includes screws for fixing of the brackets to the module, bolts for securing the module in the rack and cable tidy brackets..

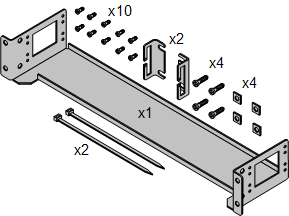

Barrier Box Rack Mounting Kit

|

•Barrier Box Rack Mounting Kit (SAP 700293905) |

Environmental Requirements

In addition to the existing environmental requirements for an IP Office system, the following additional factors must be considered when rack mounting a unit:

1.Rack Positioning - Ensure compliance with the rack manufacturers safety instructions. For example check that the rack legs have been lowered and fixing brackets have been used to stop toppling.

2.Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack environment may be greater than room ambient. Therefore, consideration should be given to installing the equipment in an environment compatible with the maximum ambient temperature (Tma) specified by the manufacturer.

•o Operating Temperature: 5°C (40°F) to 40°C (104°F).

•o Operating Humidity: 10% to 95% non-condensing.

3.Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow required for safe operation of the equipment is not compromised. Proper ventilation must be maintained. The side ventilation slots on the IP500 control unit should not be covered or blocked.

4.Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not achieved due to uneven mechanical loading.

5.Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit and the effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this concern.

6.Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention should be given to supply connections other than direct connections to the branch circuit (e.g. use of power strips).

7.![]() Only the screws provided with the mounting kit should used to attach the brackets to the control unit.

Only the screws provided with the mounting kit should used to attach the brackets to the control unit.